EXECUTIVE SUMMARY

Modernization vs. Digital Transformation:

Debunking Myths and Choosing the Right Digital Strategy

Modernization vs. Digital Transformation: Debunking Myths and Choosing the Right Digital Strategy

Speakers

Context

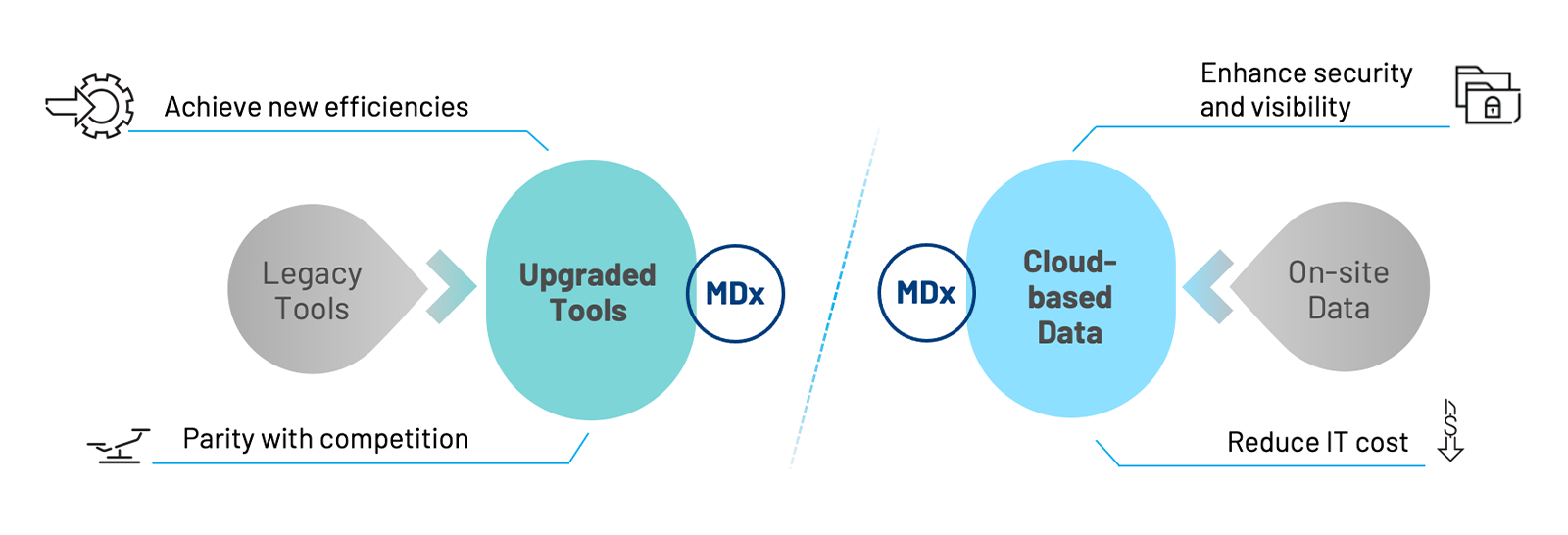

Digital transformation is fundamentally different than modernization.

- Ian Fountain, Director of Digital Transformation, Rockwell Automation

Modernization is often driven from the bottom up while digital transformation is driven from the top down.

When top leadership promotes digital transformation, they generally try to do one of the following:

Manufacturers in all industries are looking to provide increased packaging flexibility through end-of-line automation solutions.

Erector portfolio

Palletize portfolio

Technical risk reduction

Machine-as-a-service

- Brian Patrick, VP of Engineering, Pearson Packaging Systems

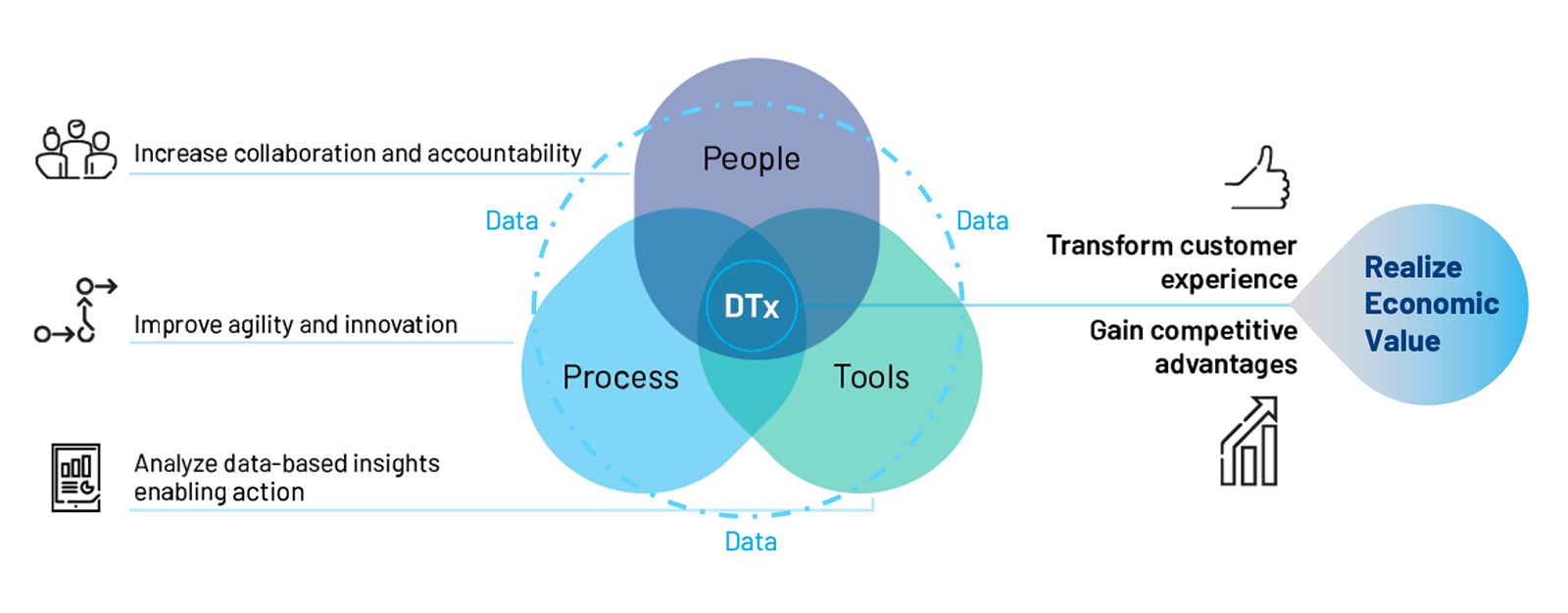

Eight lessons learned from successful digital transformations.

Kalypso, Rockwell Automation’s consulting and system integration arm, specializes in executing digital transformation programs. Steve Riordan shared eight lessons learned from Kalypso’s work.

The factory must lead the initiative.

Digital transformation has to be a collaboration between leaders at the factory and those in the corporate functions. But the leaders at the factory can’t be passive; they must lead.

Avoid overdoing the plan; embrace learning.

Ideally, an organization doing transformation has a vision, a direction, prioritization of use cases, and a good business case and roadmap. Then, the key is to start executing against digital transformation use cases.

Not one, not many, but the proper technology.

A digital transformation typically consists of several use cases, each of which may have more than one technology. New technology must interface with the existing backbone and be of value to achieve defined objectives.

Collaboration across divisions is key.

The key is collaboration that is cross-functional and cross-organizational so that everyone is working together. Open communication of pilot programs throughout divisions allows for sharing of valuable experience and knowledge.

Get beyond the pilot and assume variation.

An over-extended pilot stage delays the full delivery of value. The idea is to try to get out of pilot purgatory by demonstrating success with a minimum viable product against a few use cases and then quickly figure out how to scale. Use all of the learnings from the pilot, but don’t get stuck in the pilot.

Integrate data governance.

Data governance and standards need to be key considerations at the core of a smart factory. This requires being thoughtful about how data is structured and governed so that the organization’s data is a valuable resource to support digital transformation.

Create smart factory experiences.

Once the value is proven using new technology, create widespread demonstrations of success to build momentum.

Communicate progress and celebrate success.

Recognize success early and clearly communicate decisions to replicate POVs.

- Steve Riordan, Principal & Global Practice Leader, Consulting and Supply Chain, Kalypso

Additional Resources

Buckle Up:

Quality is Driving Digitalization

The speakers discussed differences between modernization and digital transformation, described flexibility advantages of end-of-line automation solutions, and shared lessons learned from successful digital transformations.

Achieving Results with Smart Manufacturing

Smart Manufacturing represents the integration of three key productivity factors: Automation, Operations Information, and Advanced Analytics. Learn how to reap the benefits when these factors work together in real-time.